Research & Development

Advancing Inductor Technology of Research and Innovation for Next-Generation Solutions

ABC's R&D team has extensive experience in the design and technology of inductive components and holds a number of patents, as well as the establishment of materials laboratories and cooperation with research institutes to jointly develop basic materials for their applications. We aspire to be an inductive technical advisor to our customers in the design phase of new products.

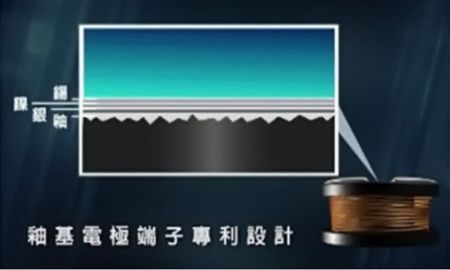

Glazing Metalize Terminal

Ferrite body coating with glazing paste is intermediate material between ferrite & silver past, through high temp sintering and Nickel & Tin plaiting cover sequenced on the suface. This glazing metalize terminal offer strong bonding strength & high reliability.

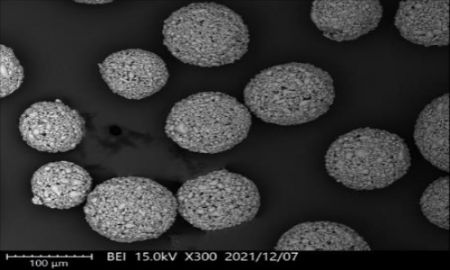

Micro porous ceramic

Apply low temp sintering process produce micro porous ceramic heat sink with Light weight , larger surface area & high insulation advantages compare with traditional alumina alloy heat sink. Improving the surface construction of silicon-carbide particle & hydrophilic binder agent to reduce solvent usage, lower sintering temp & energy consumptions.

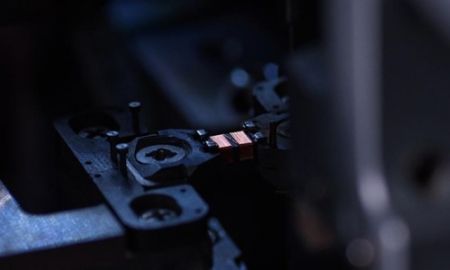

Precision Auto-winding

Use oxide alumina ceramic as coil bobbin apply high precision winding machine programmable by soft ware can do winding by spaced or closed align. Offer high quality high frequency wire wound RF chip inductor.

Toroid Auto- Bifilar-Winding

Set up mini toroid core auto winding equipment is programmable by soft ware with two windings in bifilar or separate model which get even wire arrange onto mini toroid core for common mode filter offer excellent frequency response for EMI suppression.